Zero Breakage Strategy: Logistics Engineering and Export of Moheb (Paper-Shell) Almonds to India

Within the highly volatile, risk-laden, and deeply specialized ecosystem of the Dried Fruit Global Trade, particularly across the strategic Iran-India export corridor, trading Paper-Shell Almonds has perpetually presented a profound commercial paradox. On one side lies the explosive and escalating market demand for "Convenience" and an interactive consumer experience; on the other, an extraordinarily high Supply Chain Risk associated with physical degradation.

In India's hyper-sensitive, luxury-driven, and intensely competitive market—especially during Peak Seasons such as the Diwali festival, the Wedding Season, and major religious celebrations—the Iranian Moheb Almond occupies an unparalleled position as a premium, interactive commodity for VIP Corporate Gifting. The Indian buyer willingly pays a substantial premium for a delicate shell that fractures with the gentle pressure of two fingers. However, this exact biological and competitive advantage transforms into the trader's Achilles' heel and primary source of Profit Margin Erosion if rigorous logistics engineering protocols are neglected.

The pulverization of this fragile woody shell during the extensive Maritime Transit from Bandar Abbas to Nhava Sheva or Mundra not only obliterates the uniform, luxury aesthetic of the cargo but also exposes the inner kernel to free air, marine humidity, and rapid oxidation. This inevitably triggers severe financial Claims from the Indian consignee. In this comprehensive, highly specialized white paper, the Walmond Engineering Research and Strategy Department utilizes a strictly analytical, data-driven, and industrial approach to dissect the advanced techniques of packaging optimization, thermodynamic shock containment, and the absolute minimization of the Breakage Rate in the export of Moheb almonds.

1. Biomechanical and Physical Fracture Analysis

To design a flawless, shock-proof, and secure logistics system, one must first scientifically and empirically comprehend the mechanical properties and Physical Constraints of the agricultural commodity. The Moheb almond differs fundamentally in morphological structure and cellulosic wall thickness from stone varieties, dictating a completely distinct behavior under mechanical stress.

A) Compressive Strength and Shell Yield Point

The Shell Thickness of the Moheb almond typically ranges between 0.6 to 0.9 millimeters. In precise compressive strength evaluations conducted within materials engineering laboratories, the Yield Point of this variety against static loads is assessed as extremely low. Unlike varieties such as the Shahroudi 12 Almond or the Shahroudi 7 Almond, which feature heavily lignified shells capable of easily withstanding the massive pressures of Bulk Storage in 50-kg polypropylene bags, the Moheb almond is exceptionally brittle. If subjected to the Dead Load of vertical stacking columns inside a container, the Moheb shell rapidly develops Micro-cracking along its Suture Line, inevitably leading to complete structural collapse and fragmentation.

B) Abrasion Vulnerability and Dust Generation Phenomenon

Beyond its vulnerability to vertical compressive forces, the continuous friction between shells induced by the container's Harmonic Vibration presents a far more insidious challenge. This relentless abrasion strips the velvety texture from the Moheb shell, generating fine woody dust (Dust Generation) within the packaging. The presence of accumulated dust at the bottom of the cartons is penalized heavily during the Visual Inspection by FSSAI customs officials or wholesale buyers in "Khari Baoli," directly resulting in severe Price Depreciation. To fully grasp the structural differences, financial justification, and profit margins of these varieties compared to stone almonds, reviewing the specialized article on the Economic Value Analysis: Paper-Shell vs. Stone Almonds is an absolute mandate for commercial departments.

2. Autopsy of Transit Stress Factors in the Iran-India Maritime Corridor

The multimodal transit route from Iranian orchards to the ports of Mumbai or Mundra is riddled with mechanical, dynamic, and thermodynamic stressors that directly threaten the physical integrity of the cargo. Ignoring these stressors is the primary catalyst for the tens of thousands of dollars in losses suffered by novice exporters on this route.

A) Dynamic Shocks, Impact, and Harmonic Resonance

Throughout operations such as factory Stuffing, Vessel Loading, and Discharge at destination ports, containers are manipulated repeatedly by heavy machinery. The abrupt, high-G-force jolts from Gantry Cranes, severe braking by transit trucks, and the ceaseless turbulence of ocean waves (Vessel Pitch, Roll, and Heave) impart violent dynamic shocks to the cartons. If even a few millimeters of Headspace exist within the final packaging, the almonds will collide with each other and the carton walls with every shift in acceleration, rapidly pulverizing the fragile Moheb shell.

B) Thermodynamic Fluctuations, Container Sweat, and Shell Weakening

Due to microscopic pores on its shell, the Moheb almond is highly Hygroscopic. While traversing the intensely humid maritime environments of the Persian Gulf and the Indian Ocean, severe day-night temperature differentials trigger the "Container Rain" or Container Sweat phenomenon. If the packaging lacks a robust Moisture Barrier, the paper-thin shell absorbs this distilled condensation. It loses its crunchy, brittle nature, transforming into a dark, rubbery, and highly tear-susceptible texture. Simultaneously, the permeation of moisture into the inner kernel accelerates lipid hydrolysis and spoilage. The exact details of these destructive chemical reactions and evaluation methodologies are scientifically formulated in the reference article: How to Detect Fresh vs. Stale Almonds.

3. Industrial Packaging Architecture: The Engineered Zero-Breakage Solution

Relying on standard 30-kg or 50-kg PP (Polypropylene) bags—traditionally utilized for stone varieties—is tantamount to "Commercial Suicide" when exporting Moheb almonds. At the Walmond brand, we deploy a multi-layered, intelligent, and highly engineered Packaging Architecture to entirely neutralize physical risks at the source.

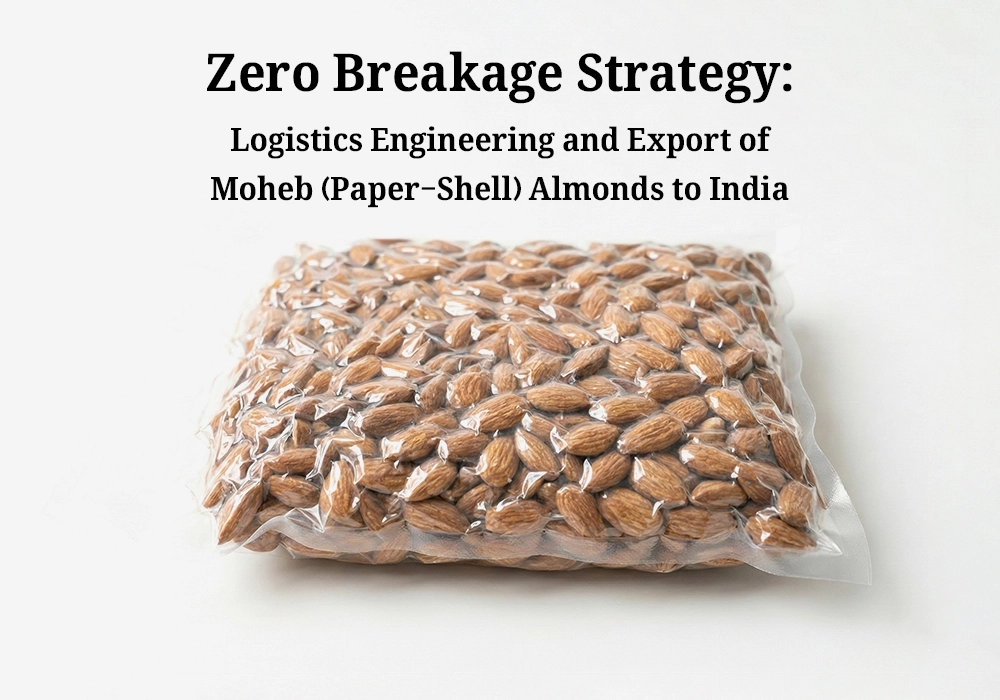

A) Primary Packaging: Zero-Headspace Policy and MAP

The foremost engineering law in preventing breakage of fragile cargo is the absolute immobilization of the product.

- High-Barrier Polymeric Liners (PE/PET): The Moheb almonds are first deposited into thick, multi-layered plastic liners (with precisely calculated micron thickness) offering absolute resistance against the ingress of atmospheric moisture and oxidative gases.

- Modified Atmosphere Packaging & Partial Vacuum (MAP): Once the liner is filled, the internal air is evacuated and replaced with an inert gas (such as Nitrogen), followed by the application of a partial vacuum. This technique forces the Moheb almonds to interlock densely. This Interlocked matrix eliminates any free space, preventing collision, sliding, and abrasion throughout the 20-day maritime journey.

B) Secondary Packaging: Engineered Corrugated Boxes with High BCT

The secondary packaging must be designed to bear the entire Stacking Load of the container without transferring a fraction of a Newton of force to the sensitive commodity inside.

- High-Grammage Kraft Boxes: We utilize 5-Ply or 7-Ply corrugated cartons manufactured from high-grammage Kraft paper (e.g., 150+ GSM). These cartons feature exceptionally high Box Compression Test (BCT) and Edge Crush Test (ECT) ratings, preventing any outward bulging under severe static pressure.

- Optimal Weight Distribution: Unlike bulk cargoes packed in heavy units, Walmond's Moheb almonds are packed exclusively in cartons with a maximum Net Weight of 10kg. This dramatic reduction in unit weight prevents the creation of a concentrated Point Load on the bottom layer of almonds, thereby guaranteeing the physical integrity of the lowermost strata.

C) Tertiary Packaging: Palletization, Unitization, and Vibration Dampening

The Containerization process must never be floor-loaded; it requires systematic, palletized integration.

- Interlocking Stacking Pattern: Cartons are arranged in a cross-stacked configuration on standardized, fumigated wooden or plastic pallets to form a stable, interwoven structure.

- Structural Edge Protectors (Corner Boards): Rigid, compressed cardboard edge protectors are applied to all vertical corners and horizontal edges of the pallet, fortifying the overall structure against sudden forklift impacts, heavy strapping tension, and lateral shear forces.

- Dynamic Stretch Wrapping: The entire pallet is securely swathed in multiple layers of high-tensile industrial Stretch Film. This dampens the vessel's harmonic vibrations and forces the entire pallet to react to lateral sway as a single, rigid, Unitized Load.

4. Laser Sorting and Calibration: The Hidden Prerequisite for Safe Packaging

A proven engineering axiom governs food logistics: Even encapsulated within the world's most expensive packaging, an uncalibrated cargo will suffer internal breakage. Why? During the ceaseless vibrations of transit, smaller kernels continuously migrate into the voids between larger kernels (the Settling phenomenon). This disrupts the pressure equilibrium within the carton matrix, leading to the crushing of weaker, misaligned shells.

A) Precision Sizing via Industrial Vibratory Screens

At Walmond's advanced processing facilities, the Moheb almond cargo undergoes rigorous calibration through multi-stage vibratory sieves prior to entering the packaging line. When all kernels within a carton possess a perfectly Uniform Count, diameter, and dimension, the ambient static pressure is distributed evenly and homogeneously across all nuts (Uniform Load Distribution). Consequently, no single kernel is subjected to multiplied, localized pressure.

B) Laser Eradication of Defects and Twin Kernels

Deformed, broken, chipped, and twin almonds possess sharp angles and asymmetrical edges. Amidst the continuous vibrations of maritime transport, these sharp protrusions act like scalpels, lacerating the fragile shells of adjacent healthy almonds. The deployment of AI-sensor-equipped Laser Sorters to definitively eradicate these defects before packaging is an absolute necessity. For a deeper understanding of the destructive financial impact of twin kernels on final cargo valuation, reviewing the specialized white paper on the Impact of Twin Kernels on Export Almond Pricing is highly recommended.

5. Financial Risk Analysis and Claim Matrix in the Indian Market

Indian traders, wholesalers, and importers are notoriously conservative, meticulous, and calculative when evaluating quality. What financial catastrophe strikes a trader's P&L (Profit and Loss) statement if a container of Moheb almonds arrives in Delhi or Mumbai with 10% to 15% breakage?

The Claim and Penalty Matrix in India

In the ruthless arena of B2B negotiations with Indian buyers, a Broken Shell is not merely a superficial cosmetic flaw. A broken shell signifies the direct exposure of the kernel to ambient air, inciting rapid lipid rancidity, drastically elevating the risk of Aflatoxin generation, and providing an ideal gateway for warehouse pests (such as the Indianmeal moth).

- Direct Deduction: Within the customary practices of the Indian wholesale market, for every 1% of breakage exceeding the permissible threshold (the Standard Tolerance for paper-shell varieties is typically negotiated below 2%), the Indian buyer claims the right to deduct a penalty of at least 1.5% to 2.5% from the total Commercial Invoice value, or demands re-sorting at the seller's expense.

- Grade Downgrade and Value Destruction: Should the breakage rate in a specific batch exceed the 15% threshold, the entire shipment is stripped of its "In-shell Premium Nut" status. The buyer unilaterally downgrades it to an Industrial Grade commodity meant for shelling or oil extraction—a catastrophic reclassification that inflicts a 30% to 40% depreciation on the exporter's principal capital.

Cost-Benefit Analysis and ROI of Luxury Packaging

The Chief Financial Officer of a novice exporting firm might erroneously classify the use of 7-ply Kraft cartons, imported vacuum-seal liners, standardized palletization, and edge protectors as an unnecessary Overhead Cost that artificially inflates the FOB price. However, on an 18-ton container where the C&F (Cost and Freight) value frequently exceeds $100,000 to $120,000, investing $1,500 to $2,000 in flawlessly engineered packaging is essentially purchasing inexpensive Profit Margin Insurance. This intelligent investment shields your organization from devastating $20,000 to $30,000 Claims at the destination port.

6. Strategic Comparison: In-Shell vs. Shelled Export Operations

A strategic dilemma frequently encountered by Supply Chain Directors is this: From a business perspective, wouldn't it be safer and more cost-effective—eliminating the headache of Moheb shell breakage and optimizing container volume—to mechanically shell the almonds in Iran and export them to India as a pure Shelled commodity?

Deep Comprehension of User Intent and Market Psychology

The answer is an unequivocal negative; the rationale is deeply rooted in Indian Consumer Behavior and market psychology. In the Indian ecosystem, almonds targeted for industrial applications (oil extraction, confectionery, slicing) or the routine daily consumption of the middle class are logically imported in shelled form (e.g., California, Australian, or Shahroudi 7 varieties). Conversely, if the affluent Indian consumer's objective is to procure a super-luxury, organic, and therapeutic kernel, they will unhesitatingly gravitate toward the market's flagship: the Mamra Almond.

However, the commercial identity and psychological positioning of the Moheb Almond in India are defined entirely differently. This product is an Interactive Commodity. The tactile satisfaction of fracturing the paper-thin shell with a simple pinch on a living room table, hearing the crisp snap, and extracting a fresh kernel is an inextricable component of the product's User Experience (UX). Within exorbitant Diwali Gift Hampers presented to executives and business partners, the presence of the in-shell almond stands as the undisputed symbol of authenticity, zero human tampering, and Untouched Quality & Purity. Therefore, exporting shelled Moheb almonds effectively obliterates its Value Proposition and Niche Market status in India, plunging your product into a Red Ocean of ruthless price wars against cheaper American varieties, ultimately guaranteeing commercial failure.

7. Advanced Quality Assurance and Engineering Protocols at Walmond

At the Walmond brand, the export of Moheb almonds is not viewed merely as a freight forwarding operation; it is treated as a Precision Engineering Project. Our rigorous Quality Assurance (QA) protocols, designed to guarantee the arrival of 100% intact cargo at the ports of Nhava Sheva or Mundra, encompass the following stringent stages:

- Drop Test and Impact Simulation: Prior to final packaging approval, randomized samples of fully packed cartons undergo standardized drop tests from a height of 1.5 meters onto concrete surfaces (simulating a drop by a laborer or forklift). This verifies the structural integrity of the corrugated box and the absolute safety of the internal kernels before mass loading.

- Precise RH and Dew Point Control: Pre-packaging, the kernel's internal moisture is meticulously calibrated to 5%, while the woody shell's moisture is stabilized at an optimal equilibrium—ensuring it is neither so desiccated that it pulverizes under harmonic vibration, nor so damp that it fosters fungal blooms and dangerous Aflatoxin synthesis within the container.

- Smart In-Container Data Loggers and Real-Time Tracking: For high-value, highly sensitive shipments requiring specialized custody, digital temperature and humidity logging sensors are affixed to the container's interior walls throughout the maritime voyage. These sensors record any Atmospheric Deviations for future logistical refinement and, if necessary, substantiation in Marine Insurance Claims.

8. Executive Conclusion and Roadmap for Commercial Departments

The export of Paper-Shell (Moheb) almonds to India is a logistical minefield that can only be traversed successfully and profitably by exporters and traders armed with cutting-edge logistical science, maritime transit expertise, and materials engineering mastery.

For Indian traders and wholesale Importers situated in Delhi and Mumbai, procuring deceptively cheap Moheb almonds at the origin—carelessly packed by intermediaries in substandard gunny bags or flimsy cartons devoid of vacuum architecture—is the definitive equivalent of purchasing waste, alienating luxury corporate clients, and squandering vast amounts of Working Capital.

The triumphant and sustainable strategy in this trade necessitates an immediate cessation of focus on the raw FOB price, pivoting instead to absolute focus on the Landed Cost and Realized Value. This entails calculating the mathematical final cost of the goods in your warehouse after deducting the penalties for breakage waste and destination re-sorting expenses. A cargo that arrives at your facility with zero percent breakage, zero dust generation, and the highest visual standards will unequivocally prove to be the cheapest, most secure, and most lucrative asset at the close of the fiscal year.

Call to Action for Indian Traders: If you are a trader, wholesaler, or Supply Chain Director in India seeking the stable, fluctuation-free, and secure procurement of calibrated Moheb almonds—backed by a written guarantee of "Sub-2% Breakage" upon arrival at Nhava Sheva Customs—Walmond's logistics architecture, optical sorting standards, and multi-layer packaging are engineered precisely for your business model. To request Industrial Packaging Samples, view our BCT Box Compression Test videos, and receive expert consultation and financial modeling for freight cost optimization, contact the Walmond International Export Department immediately. We engineer and guarantee the security of your capital across the oceans.